Abstract

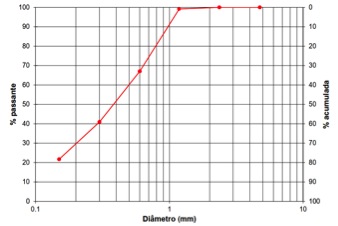

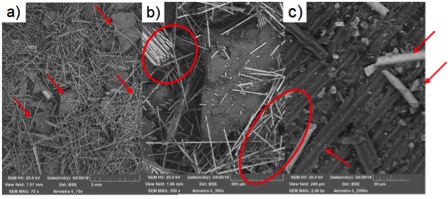

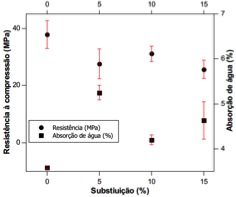

The use of polymers in industry is expanding, especially glass fiber reinforced polymers (GFRP). The production process of GFPR parts generates significant amounts of waste, which then needs to be disposed of in industrial landfills, which both generates financial costs for the industrial sector and constitutes an environmental problem. The search for solutions that incorporate the waste either in the process or as a substitute for raw materials is one of the current concerns of research into materials. This study evaluates the application of GFRP waste in concrete mixtures for the production of interlocking pavers. The waste presented fine aggregate granulometry, with a fineness modulus of 1.71. The morphology revealed a heterogenous surface, with granules of different sizes and smooth and elongated stems. The partial replacement of sand by GFRP residue (5%, 10% and 15%) resulted in pavers with lower compressive strength (< 31 MPa) when compared to the control specimens without GFRP, however, the strength results allow the application of pavers in places with light traffic or on sidewalks, with the advantage that these pavers are lighter.

Keywords:

Fiberglass; Fine aggregate; Paver; Concrete pieces

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Fonte:

Fonte: