Abstract:

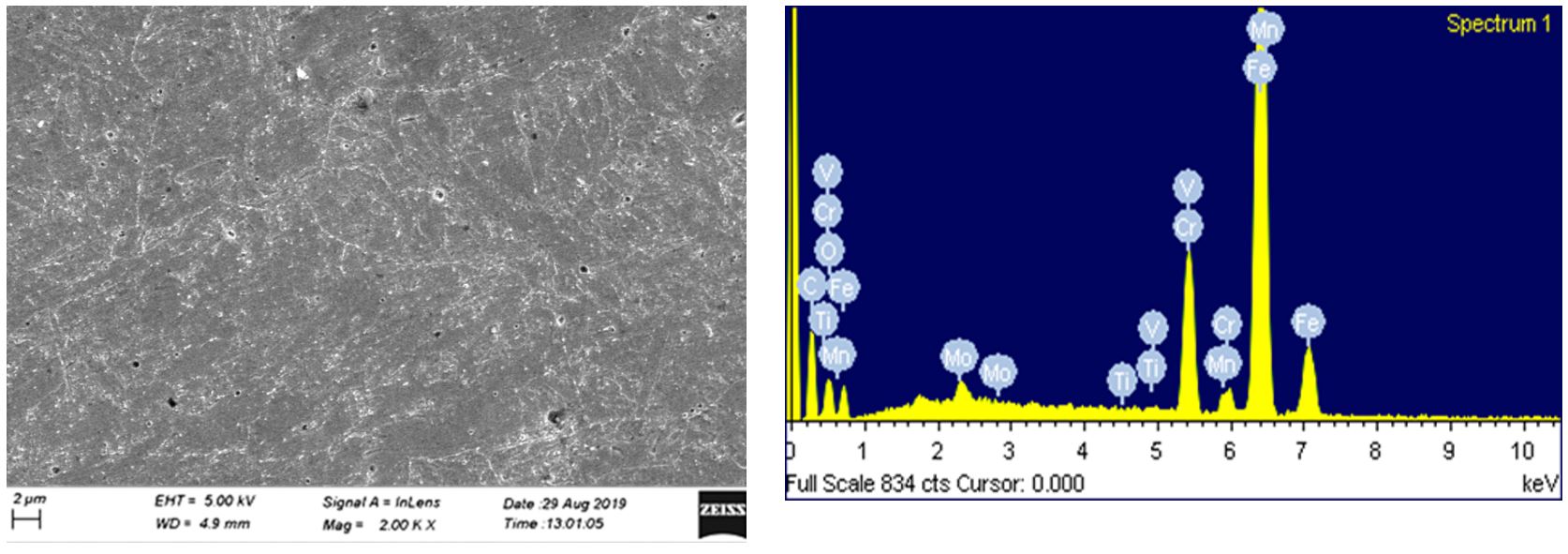

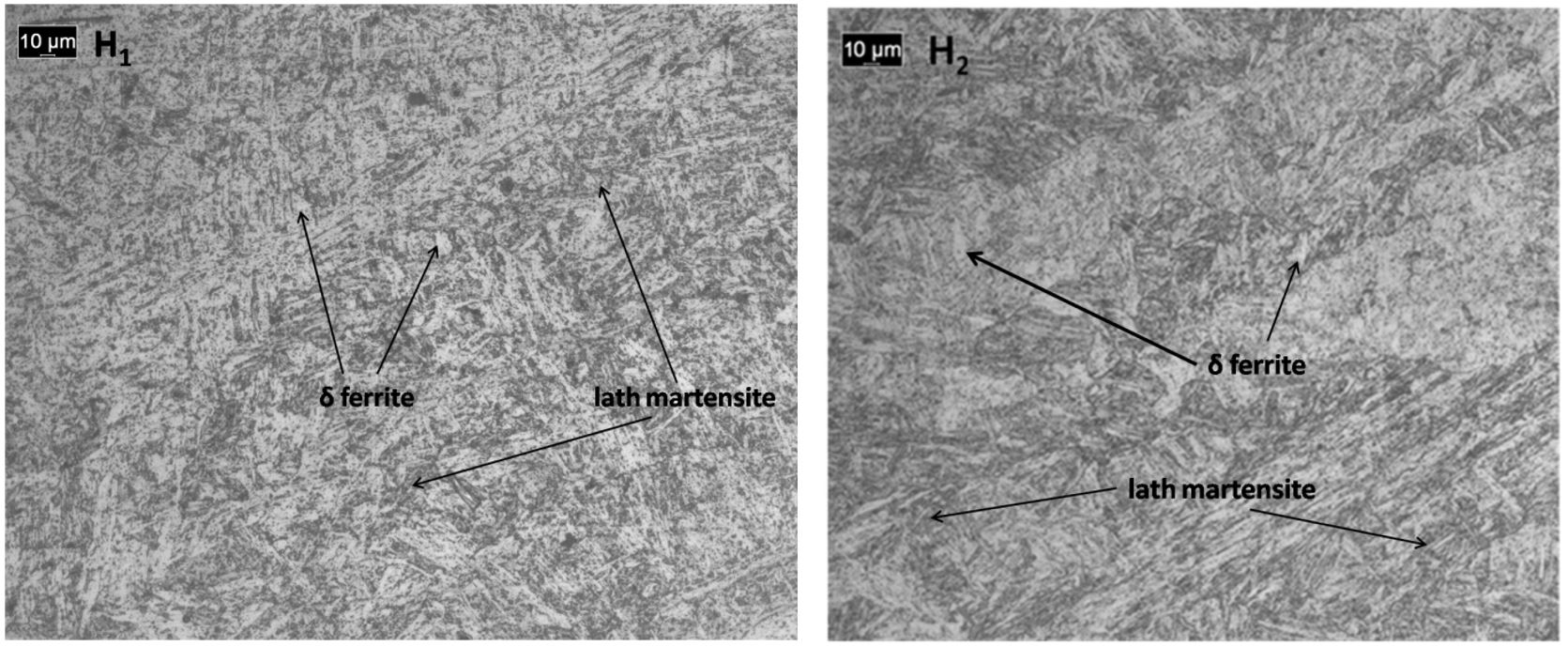

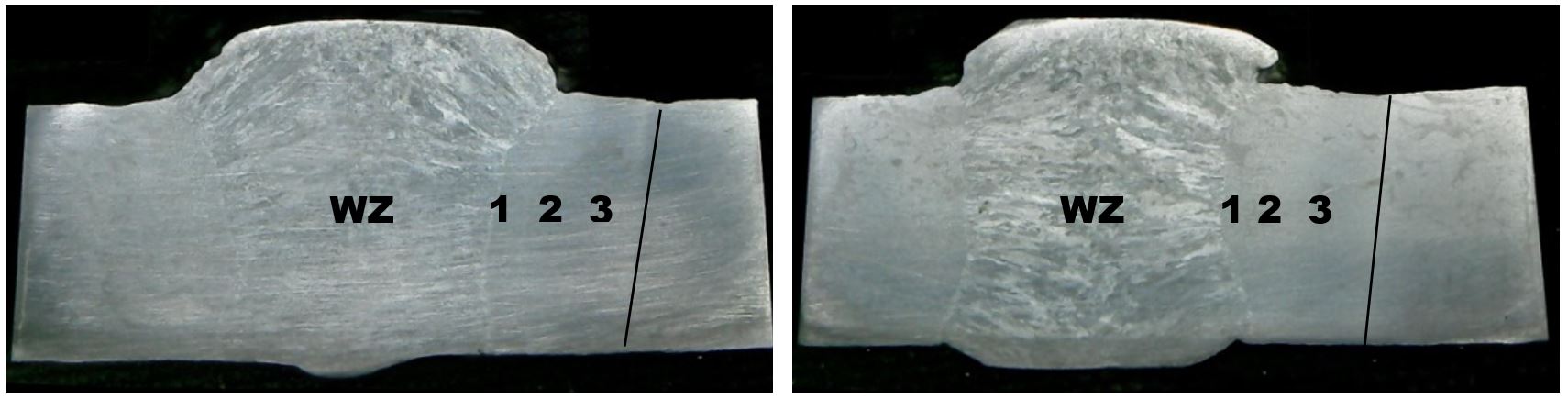

In this study, the submerged arc welded butt joint of P-91 ferritic-martensitic alloy steel plates has been chosen to examine the influence of microstructural changes on welding residual stress characteristics and macro-hardness in the weldment with two different heat input 2497.5 J/mm & 2040J/mm respectively. The stress magnitudes at a different location on the welded specimen are measured by X-ray diffraction technique at the post-weld heat-treated condition. Compressive stresses are observed in the weld zone (WZ) and tensile stresses are detected at the boundary of the heat-affected zone (HAZ) near the weld zone. Higher compressive stresses are found in the weld zone of both the specimens where maximum hardness values are observed. Different grain matrix in the microstructure contributes significantly towards the quality of weldment. Residual stress, as well as the hardness of weldment, is found to be influenced by the martensite phase transformation and dissolution of precipitates. A modeling concept is presented for dimensional analysis of martensite structure. Energy dispersive X-ray indicates the distribution of carbides at the grain boundaries. Optical micrograph substantiates the presence of δ-ferrite in the WZ.

Keywords:

Ferritic-martensitic alloy steel; Weld zone; Heat-affected zone; Microstructure; Martensite phase transformation; Macro-hardness; Welding residual stresses

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail