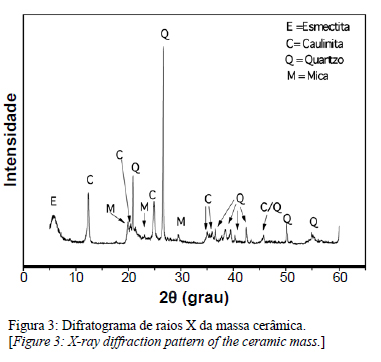

The technology that involves the use of ceramic membranes has become in the last decades an important separation technique. The main reasons in the advance of this technology are related to the fact that work without addition of chemical reagents, low consumption of energy, ease to processing and compact physical arrangements. Today the main concern in the development of these membranes is to minimize the costs and more efficient production processing. In this way the use of natural raw materials comes as an alternative to prepare ceramic membrane, using extrusion as processing technique. The aim of this work is to study the use of natural raw materials, such as, clay, quartz and kaolin to prepare tubular ceramic membranes in laboratorial scale using extrusion processing. The ceramic mass was submitted to characterizations: physical and mineralogical through particle size, thermogravimetry, X-ray diffraction and X-ray fluorescence analysis. The samples were sintered at temperatures of 800, 900, 1000 and 1100 ºC, with the aim to verify the influence on membrane characteristics. Ceramic membranes were characterized by scanning electron microscopy and mercury porosimetry, were it was possible to verify the absence of defects and cracks in its structure. In relation to the porosimetry analysis, pores in the range of ultra-filtration were observed.

ceramic membranes; ultrafiltration; characterization