ABSTRACT

The study of the corrosion of buried structures becomes necessary as their use increases. This study aims to evaluate the corrosion of AISI 304 stainless steel samples inserted in three different types of soil (Neossolo, Cambisol and Latosol) with a forced and conventional acidic pH during a period of six months. The corrosion behavior of the stainless steel samples was verified through the potentiodynamic polarization curves and the corrosion potential. The results demonstrated that the Neossolo presented a lower corrosive potential in the six-month period analyzed in acidic and natural pH conditions. The samples in Ambisol and Latosol presented similar results in the acidic pH coding. The results did not vary significantly in soils under natural conditions due to the non-rupture of the passive Cr2O3 layer. All samples with an acidic pH presented surface corrosion pits. The study of the corrosion of buried structures becomes necessary as the use of these structures increases, especially in buried pipelines and water.

Keywords:

Corrosion; Acidic soil; Polarization curves; AISI 304; Metallurgy

1. INTRODUCTION

Corrosion can be defined as the deterioration of a material, generally metallic, due to the chemical or electrochemical action of the environment, combined or not with mechanical stress [1]. Since corrosion is generally a spontaneous process, it is constantly transforming metallic materials so that their durability and performance no longer satisfy the purposes for which they were intended [1, 2]. Underground installations represent large investments that require durability and corrosion resistance that justify the amounts invested [2, 3]. Corrosive processes can be maximized when applying steel to soils in normal conditions or with an acidic PH. Soils called neosolo, cambisolo, and oxysolo can be directly influenced by their PH. They are characterized by their morphological characteristics. The Neosol, consisting of mineral material or thin organic material, has insufficient manifestation of the diagnostic attributes that characterize the different soil formation processes, whether due to greater resistance of the source material or other formation factors (climate, relief, or time) that can prevent or limit soil evolution [4, 5]. Cambisols are poorly developed but still present characteristics of the original material (rock), as evidenced by the presence of primary minerals. They vary from shallow to deep soils, normally having low permeability. They are identified in different environments, being normally associated with areas with very busy reliefs (wavy to mountainous) but can, however, occur in flat areas (lowlands) outside the influence of the water table [4, 5]. By wire, the oxidation is formed by the process called latolization, which basically consists of the removal of silica and the bases of the profile (Ca2+, Mg2+, K+) after the transformation of the constituent primary minerals. Its general characteristics are clays with a predominance of iron, aluminum, silicon, and titanium oxides; low-activity clays (low CEC); strongly acidic; and low base saturation. It is the most common type of soil in Brazil and is divided into four orders: Brunos, Amarelos, Vermelhos, and red-yellows [4, 5]. In this sense, stainless steel installations are a good option as they promote long-term savings, quality, and durability of the installation, in addition to being hygienic, adaptable, and recyclable [4, 5]. The use of buried stainless steel structures occurs on a limited basis but is becoming more common due to their ability to resist corrosion, which is necessary especially in aggressive environments such as proximity to salt water, highly polluted places, and acidic soils [4, 5]. Use has also been growing in water pipes, especially after successful cases have already been implemented, such as in Tokyo (Japan) and Seoul (Korea), where all pipes have already been replaced by stainless steel, or in Taipei (Taiwan), where it is in the process of implementation, expected to be completed in 2025, according to the water management department in Taipei [4, 5]. Soil corrosion is a complex phenomenon due to the range of heterogeneous factors involved, such as unit content, pH, electrical resistivity, chloride and sulfate content, plasticity index, organic content, and percentage composition of elements, among others [1–5]. Furthermore, one of the important factors is the presence of chloride and sulfide anions in the aqueous solution. Chlorides play an important role in the corrosion of stainless steels because passive films are easily destroyed by this anion [1–3]. In acidic environments, there is a fundamental difference in the behavior of stainless steels. On the one hand, acidic oxidizing media help to form (or preserve) the passive film, as is the case with nitric and phosphoric acids. On the other hand, acid-reducing media do not allow its formation (or destroy it) [1, 3, 6].

As an example of the latter case, we can mention hydrochloric and hydrofluoric acids. In sulfuric acid, a very reducing acid, stainless steels such as 304 and 316 only resist very dilute or very concentrated solutions at low temperatures. The corrosion of stainless steels in reducing acid media always presents a generalized, uniform character. If the stainless steel already has a passive film, the attack will cause oxygen vacancies in the film as well as in non-ferrous alloys such as aluminum and titanium [7, 8]. In media containing chloride anion, stainless steels are at risk of suffering localized forms of corrosion (such as pitting and crevice corrosion). In this case, the attack will cause metallic gaps in the passive film. The rate of vacancy creation increases with the concentration of chlorides in the medium. The base metal migrates, occupying these gaps and eliminating them. The concentration of metallic vacancies will depend on the speed of their creation and elimination. If the speed of creating gaps is predominant, the passive film loses cohesion and ends up suffering localized ruptures [9]. Stainless steels are classified according to their alloy elements as ferritic, austenitic, duplex, precipitation hardening, and martesitic [8–10]. Austenitic stainless steels have their corrosion resistance obtained from the Cr2O3 layer that forms a barrier for the substrate, which is formed naturally by mechanical or chemical means for passivation. In austenitic stainless steels, after welding processes, the application of solubilization heat treatment is recommended, avoiding the phenomenon of sensitization and subsequent intergranular corrosion [1–3]. Its hardening mechanism occurs through plastic deformation and may result in specific situations, in addition to the austenitic microstructure, in the presence of deformation-induced austenite (MID) [1–3]. The preliminary condition of stainless steels, their mechanical forming process, and their chemical balance can directly influence their performance against corrosion. Along with these factors, application environments also stand out for how much they can compromise the passivated oxide layer on the surface [8, 10]. This research aims to map the behavior of AISI 304 austenitic stainless steel in the raw condition of mechanical rolling applied in different soils (Neosol, Cambisol, and Oxisol) with PH 2 (acid) and in soil with natural PH. It also seeks to contribute to the determination of the surface morphological behavior of AISI 304 austenitic stainless steel in terms of the presence of increased corrosion kinetics. There are research gaps regarding the use of AISI 304, which is the most versatile austenitic stainless steel and has a lower cost than those with better chemical balance, such as AISI 316 L.

2. MATERIALS AND METHODS

Soil collection was carried out after removing vegetation cover. Subsequently, a small sample of each soil was taken and sieved, as shown in Figure 1a. A 10 ml pipe was used, filling it completely with soil. Then, 2 ml of deionized water was added, equivalent to 20% humidity. Afterwards, it was transferred to the centrifuge tube, adding 25 ml of water. It was stirred in the shaker for 5 minutes, as shown in Figure 1b, and after this time, the PH meter was read for 30 minutes.

Demonstration of the sieving process (a) and soil homogenization used to evaluate the behavior of AISI 304 steel (b).

To calibrate the PH meter, standard solutions of PH 4 and 7 kept in refrigeration are used. These solutions must be used at room temperature, waiting at least 3 hours for the temperature to stabilize. Clean the electrode, dry it on a paper towel, insert it in the PH 4 solution, and take the reading. Next, the same procedure is carried out using the PH-7 solution. After this procedure, the preparation of the acid solution for acidification of the samples began, being applied to each of the three soils studied using 4% HCl and targeting obtaining PH 2. Another three samples were tested in the soil under normal extraction conditions, measuring the PH of each of them. To prepare the austenitic stainless steel samples, they were cut with dimensions of 50 × 50 × 5 mm. The first step was to check the chemical composition of the steel AISI, ensuring that it had the specified quantities. In this way, samples of the material were subjected to optical spectrometry using the Foundry-Master Pro optical spectrometer. The results measured in the test were compared with limits established by ASM for AISI 304 steel. To perform the surface analysis, an optical reflected light microscope, an Olympus GX 51S, and image analysis software were used. The electrochemical tests were conducted on an Autolab PGSTAT302N potentiostat using a three-electrode electrochemical cell, using a saturated calomel electrode as a reference and a platinum rod as a counter electrode. The electrolyte used was a 0.1 mol/L NaCl solution with PH 5.7 at a temperature of 22 °C. The OCP open circuit potential was monitored for 3600 seconds, followed by cyclic potentiodynamic polarization, starting from 300 mV cathodic with respect to the OCP to 3000 mV anodic with respect to the OCP under a scan rate of 1 mV/s. The assay was set to reverse the direction of the scan when the run reached 0.01 B C−2.

3. RESULTS AND DISCUSSIONS

No segregation of the chemical elements of the alloy that could directly influence the test results was detected in the chemical composition. The chemical composition of the steel meets all the requirements of the AISI 304 standard (Table 1). The microstructure of the samples consists of stable austenite, and the presence of MID is not detected. This condition indicates that the AISI 304 stainless steel is in the solubilized condition [7–11]. No deformed grains were detected on the surface of the samples, indicating that the steel underwent dynamic recovery and recrystallization stages in the homogenization stage during heating to solubilize the steel [3, 9, 12]. In the analysis of the surface of the samples submitted to soils with PH2 for six months, all showed the presence of corrosion pits, as shown in Figure 2a. In the samples subjected to interaction with the soil in a natural state, no corrosion pits were detected. In Figure 3b, the corrosion pits can be seen on the surface of the parts. In all stainless steel samples submitted to soils with acidic PH, corrosion pits were detected, which only showed variations in size as indicated in Table 2.

Corrosion pits in samples submerged for six months in soil with PH 2 at different magnifications.

Potentiodynamic polarization curve of the AISI 304 steel sample subjected to soil in natural and with PH2.

Table 2 shows the diameters of the corrosion pits in time and in the soil to which they were exposed. The largest pit diameters were detected in samples submitted to Neossolo and Cambisol with PH2 for six months. These two soils are characterized by being more influenced by variations in PH in the Neosol and the condition of the water table in the Cambisol [4, 5, 10, 13, 14]. Pits are characterized by being stress concentrators and nucleation points for hydrogen embrittlement, mainly in martensitic, precipitation-hardened, and duplex stainless steels [3, 9–15]. In austenitic stainless steels, embrittlement sometimes does not represent a significant risk; however, in cases where MID is present, hydrogen embrittlement phenomena may occur [3, 9–15]. It is important that the presence of hydrogen, which has a reduced atomic radius, is progressive and cumulative and can cause failures over longer exposure times in components, even in austenitic stainless steels that have notched elements, right angles, or threads with or without the application of heat treatments [10, 11, 15, 16–17].

The results of the potentiodynamic polarization curves for six months of the AISI 304 austenitic stainless steel sample in the fluvic neosol natural and with PH2 can be seen in Figure 3. The corrosion current of this soil was determined with Icorr values of 0.25 µA/cm2 (PH2) and 0.15 µA/cm2 (normal soil). It can be clearly seen that the corrosion current values in samples subjected to normal conditions contribute to maintaining the integrity of the Cr2O3 layer [9].

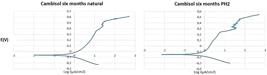

The results of the potentiodynamic polarization curves for six months of the AISI 304 austenitic stainless steel sample in the dystrophic Haplic Cambisol natural and with PH2 can be seen in Figure 4. The corrosion current of this soil was determined with Icorr values of 0.49 µA/cm2 (PH2) and 0.44 µA/cm2 (normal soil). It can be clearly seen that the corrosion current values in samples subjected to normal conditions contribute to maintaining the integrity of the Cr2O3 layer [9]. The Icorr values were higher when compared to the exposure in the Fluvic Neosol.

Potentiodynamic polarization curve of the AISI 304 steel sample subjected to soil in natural and with PH2.

The results of the potentiodynamic polarization curves for six months of the AISI 304 austenitic stainless steel sample in dystrophic yellow oxide natural and with PH2 can be seen in Figure 5. The corrosion current of this soil was determined with Icorr values of 0.50 µA/cm2 (PH2) and 0.43 µA/cm2 (normal soil). It can be clearly seen that the corrosion current values in samples subjected to normal conditions contribute to maintaining the integrity of the Cr2O3 layer [9]. The Icorr values were higher when compared to exposure in Fluvic Neossolo and show similarity in Dystrophic Haplic Cambisol applications [4–6].

Potentiodynamic polarization curve of the AISI 304 steel sample subjected to soil in natural and with PH2.

Even with a lower corrosion current, the corrosion pits in Neossolo had similar diameters to those in Cambisol but a smaller volume of corrosion pits. The diameter of the pits in the Oxisol samples showed a smaller diameter but a greater volume of pits. These characteristics are directly influenced by the morphological elements of each soil, with Neosol being less aggressive with PH2 [4–6, 10–17]. Overall, the results revealed that the influence of c-elements, such as pH and soil moisture, on steel corrosion is well captured by the soil medium in contrast to the simulated solution, resulting in differences in corrosion rates. Although the contribution of soil particles and burial depth is considered less significant for the corrosion rates of buried steel, it is important to highlight that varying the burial depth can generate different corrosion rates [8]. The deposit of corrosion products near pitted regions can somewhat protect the stainless steel from further corrosion, resulting in a reduction in local current density. With sufficiently large applied loads, it is possible to generate separate cathodes and anodes on the steel surface covered by the corrosion product [13]. Electrochemical studies make a strong contribution to the understanding the development of corrosion over time is not possible in field exposures where corrosion is only monitored or measured at the end of testing. The various methods show transitions over time, with the corrosion rate depending on environmental conditions. A common trend is the formation of a porous oxide layer and a decrease in electrochemical current over time. One of the limiting factors controlling corrosion appears to be the diffusion of oxygen through the porous layer and the soil. separating the metal surface from the air. Electrochemical studies have also highlighted the contribution of environmental parameters in promoting corrosion, in particular water acidity and pore morphology, especially when derived from acid rain in the soil [10, 11, 14, 18]. Aspects related to the manufacturing processes used in steels can also interact significantly in the behavior of austenitic stainless steels [8, 19, 20, 21, 22–23]. Corrosion under the conditions studied can also be influenced microbiologically. This phenomenon is usually caused by bacterial adhesion and biofilm formation, which can occur in different natural environments and those subjected to acidic PH [24–25].

4. CONCLUSIONS

Based on the results and discussions of the behavior of AISI 304 steel immersed for 6 months in Neossolo, Cambisol and Oxisol soils with acidic and natural PH2, the following conclusions were obtained:

The AISI 304 stainless steel samples presented a chemical composition within the specified range, being free of carbides in the grain boundaries;

After 6 months of exposure, the Neossolo, Cambissolo, and Latossolo soils with PH2 show pits on their surfaces;

The samples exposed to the three soils in natural conditions did not show surface corrosion pits;

Neossolo soil has a lower corrosive potential for AISI 304 stainless steel and, consequently, better corrosion resistance when compared to Cambissolo and Oxisol soils exposed to acidity for 6 months;

Cambisol and Latossolo soils show similar behavior in all types of exposure;

Soil corrosion can be related to a number of factors, including soil resistivity, the presence of dissolved salts, moisture content, pH, oxygen concentration, and the presence of bacteria. However, the only factor consistently found to control the corrosion of ferrous metals is soil moisture content.

5. BIBLIOGRAPHY

-

[1] AZOOR, R.M., DEO, R.N., BIRBILIS, N., et al, “On the optimum soil moisture for underground corrosion in different soil types”, Corrosion Science, v. 159, pp. 108116, 2019. doi: http://doi.org/10.1016/j.corsci.2019.108116.

» https://doi.org/10.1016/j.corsci.2019.108116 -

[2] ANDRADE, A.D.S., MEDEIROS, J.L., BIEHL, L.V., et al, “Análise mecânica e metalúrgica da união soldada entre um aço inoxidável duplex S32205 com metal de adição de aço inoxidável superaustenítico ER-385-904L”, Matéria, v. 28, e20220307, 2023. doi: http://doi.org/10.1590/1517-7076-RMAT-2022-0307.

» https://doi.org/10.1590/1517-7076-RMAT-2022-0307 -

[3] GONÇALVES, R.V., MEDEIROS, J.L.B., BIEHL, L.V., et al, “Aplicação de soluções poliméricas na têmpera do aço inoxidável 17 4 PH solubilizado”, Matéria, v. 27, n. 2, e202147233, 2022. doi: http://doi.org/10.1590/1517-7076-rmat-2021-47233.

» https://doi.org/10.1590/1517-7076-rmat-2021-47233 -

[4] VASQUES, G.M., DEMATTÊ, J.A.M., VISCARRA ROSSEL, R.A., et al, “Soil classification using visible/near-infrared diffuse reflectance spectra from multiple depths”, Geoderma, v. 223–225, pp. 73, 2014. doi: http://doi.org/10.1016/j.geoderma.2014.01.019.

» https://doi.org/10.1016/j.geoderma.2014.01.019 -

[5] JIMÉNEZ, A.D.L.A.C., ALMEIDA, C.D.C.L., SANTOS JÚNIOR, J.A., et al, “Accuracy of capacitive sensors for estimating soil moisture in northeastern Brazil”, Soil & Tillage Research, v. 195, pp. 104413, 2019. doi: http://doi.org/10.1016/j.still.2019.104413.

» https://doi.org/10.1016/j.still.2019.104413 -

[6] SANTOS, R.P., TUBINO, R., “Potential evaluation of the use of construction and demolition waste (CDW) n the recovery of degraded soils by mining in Brazil”, Resources, Conservation & Recycling Advances, v. 12, pp. 200060, 2021. doi: http://doi.org/10.1016/j.rcradv.2021.200060.

» https://doi.org/10.1016/j.rcradv.2021.200060 -

[7] ALMEIDA, A.K., ALMEIDA, I.K., GUARIENTE, J.A., et al, “Time of concentration model for non-urban tropical basins based on physiographic characteristics and observed rainfall responses”, Water Resources Management, v. 37, n. 14, pp. 5493–5534, 2023. doi: http://doi.org/10.1007/s11269-023-03616-8.

» https://doi.org/10.1007/s11269-023-03616-8 -

[8] SANTOS JUNIOR, A.G., BIEHL, L.V., ANTONINI, L.M., “Effect of chemical passivation treatment on pitting corrosion resistance of AISI 410 and 17-4 PH stainless steels”, Materials and Corrosion, v. 68, n. 8, pp. 824–830, 2017. doi: http://doi.org/10.1002/maco.201609388.

» https://doi.org/10.1002/maco.201609388 -

[9] TOCHETTO, R., TOCHETTO, R., BIEHL, L.V., et al, “Evaluation of the space holders technique applied in powder metallurgy process in the use of titanium as biomaterial”, Latin American Applied Research, v. 49, n. 4, pp. 261, 2019. doi: http://doi.org/10.52292/j.laar.2019.65.

» https://doi.org/10.52292/j.laar.2019.65 -

[10] WASIM, M., SHOAIB, S., MUBARAK, N.M., et al, “Factors infuencing corrosion of metal pipes in soils”, Environmental Chemistry Letters, v. 16, n. 3, pp. 861–879, 2018. doi: http://doi.org/10.1007/s10311-018-0731-x.

» https://doi.org/10.1007/s10311-018-0731-x -

[11] MEDEIROS, J.L., BIEHL, L.V., MARTINS, C.O.D., et al, “Assessment of residual stress behavior and material properties in steels produced via oxynitrocarburized metal injection molding”, Journal of Materials Engineering and Performance, v. 33, n. 15, pp. 7596, 2024. doi: http://doi.org/10.1007/s11665-024-09401-x.

» https://doi.org/10.1007/s11665-024-09401-x -

[12] SCHENEIDER, T.H., BIEHL, L.V., NEVES, E.B., et al, “Method for the determination of parameters in the sintering pross of mixtures of the elemental powders Fe-Cr and Fe-Cr-Ni”, MethodsX, v. 6, pp. 1919–1924, 2019. doi: http://doi.org/10.1016/j.mex.2019.08.009.

» https://doi.org/10.1016/j.mex.2019.08.009 - [13] WASSIN, M., LI, C., ROBERT, D., et al, “Corrosion bahaviour of pipes in soil and in simulated soil solution”, In: Proceedings of the Corrosion and Prevention, Sydney, Australia, 2017.

-

[14] COLE, I.S., MARNEY, D., “The science of pipe corrosion: a review of the literature on the corrosion of ferrous metals in soils”, Corrosion Science, v. 56, pp. 5–16, 2012. doi: http://doi.org/10.1016/j.corsci.2011.12.001.

» https://doi.org/10.1016/j.corsci.2011.12.001 -

[15] YANG, Y., CHENG, I.F., “Effect of stress on corrosion at crack tip on pipeline steel in a near-neutral pH solution”, Journal of Materials Engineering and Performance, v. 25, n. 11, pp. 4988, 2016. doi: http://doi.org/10.1007/s11665-016-2369-9.

» https://doi.org/10.1007/s11665-016-2369-9 - [16] MEDEIROS, J.L., REGULY, A., STROHAECKER, T.R., “Applying Oxi-nitrocarburizing surface strengthening process to corrosion prevetion in MIM 17-4 PH stainless steel”, Espacios, v. 36, n. 20, pp. 21, 2015.

-

[17] OLIVEIRA, R.C.L.M., BIEHL, L.V., MEDEIROS, J.L.B., et al, “Análise comparativa entre a têmpera e partição versus a têmpera e revenimento para o aço SAE 4340”, Matéria, v. 24, n. 3, e12472, 2019. doi: http://doi.org/10.1590/s1517-707620190003.0788.

» https://doi.org/10.1590/s1517-707620190003.0788 -

[18] VIEIRA, E.D.R., BIEHL, L.V., MEDEIROS, J.L.B., et al, “Evaluation of the characteristics of an AISI 1045 steel quenched in different concentration of polymer solutions of polyvinylpyrrolidone”, Scientific Reports, v. 11, n. 1, pp. 1313, 2021. doi: http://doi.org/10.1038/s41598-020-79060-0. PubMed PMID: 33446669.

» https://doi.org/10.1038/s41598-020-79060-0 -

[19] POLLNOW, E.N., CARDOSO, F.B., NEVES, E.B., et al, “Impact of incorporating FeNbC into weld flux on the abrasive wear resistance of coatings produced by SAW in a microalloyed steel”, Surface Topography: Metrology and Properties, v. 12, n. 1, pp. 015023, 2024. doi: http://doi.org/10.1088/2051-672X/ad2ec0.

» https://doi.org/10.1088/2051-672X/ad2ec0 -

[20] NEVES, E.B., POLLNOW, E.N., OSORIO, A.G., “The effect of microwave energy on sintering of an austenitic stainless steel reinforced with boron carbide”, Metallurgical & Materials Engineering, v. 28, n. 3, pp. 515, 2022. doi: http://doi.org/10.30544/766.

» https://doi.org/10.30544/766 -

[21] MOTTA, C.A.O., SOUZA, J., MARTINS, V., et al, “Enhancing composite materials through fly ash reinforcement in powder metallurgy”, Materials Chemistry and Physics, v. 307, pp. 128124, 2023. doi: http://doi.org/10.1016/j.matchemphys.2023.128124.

» https://doi.org/10.1016/j.matchemphys.2023.128124 -

[22] TOCHETTO, R., TOCHETTO, R., BIEHL, L.V., et al, “Evaluation of the space holders technique applied in powder metallurgy process in the use of titanium as biomaterial”, Latin American Applied Research, v. 49, n. 4, pp. 261, 2019. doi: http://doi.org/10.52292/j.laar.2019.65.

» https://doi.org/10.52292/j.laar.2019.65 -

[23] NEVES, E.B., BIEHL, L.L.V., OSORIO, A.G., et al, “Estudo da sinterização de uma liga Fe-22,5Cr-5,5Ni obtida pela mistura de pós elementares”, Matéria, v. 21, n. 1, pp. 185, 2016. doi: http://doi.org/10.1590/S1517-707620160001.0016.

» https://doi.org/10.1590/S1517-707620160001.0016 -

[24] YU, S., LOU, Y., ZHANG, D., et al, “Microbiologically influenced corrosion of 304 stainless steel by nitrate reducing Bacillus cereus in simulated Beijing soil solution”, Bioelectrochemistry, v. 133, pp. 107477, 2020. doi: http://doi.org/10.1016/j.bioelechem.2020.107477. PubMed PMID: 32035394.

» https://doi.org/10.1016/j.bioelechem.2020.107477 -

[25] OLIVEIRA, M.U., BIEHL, L.V., MEDEIROS, J.L., et al, “Manufacturing against corrosion: increasing materials performance by the combination of cold work and heat treatment for 6063 aluminium alloy”, Medziagotyra, v. 26, n. 1, pp. 30–33, 2019. doi: http://doi.org/10.5755/j01.ms.26.1.17683.

» https://doi.org/10.5755/j01.ms.26.1.17683

Evaluation of the behavior of austenitic stainless steel AISI 304 in different soils with acid PH

Evaluation of the behavior of austenitic stainless steel AISI 304 in different soils with acid PH