ABSTRACT

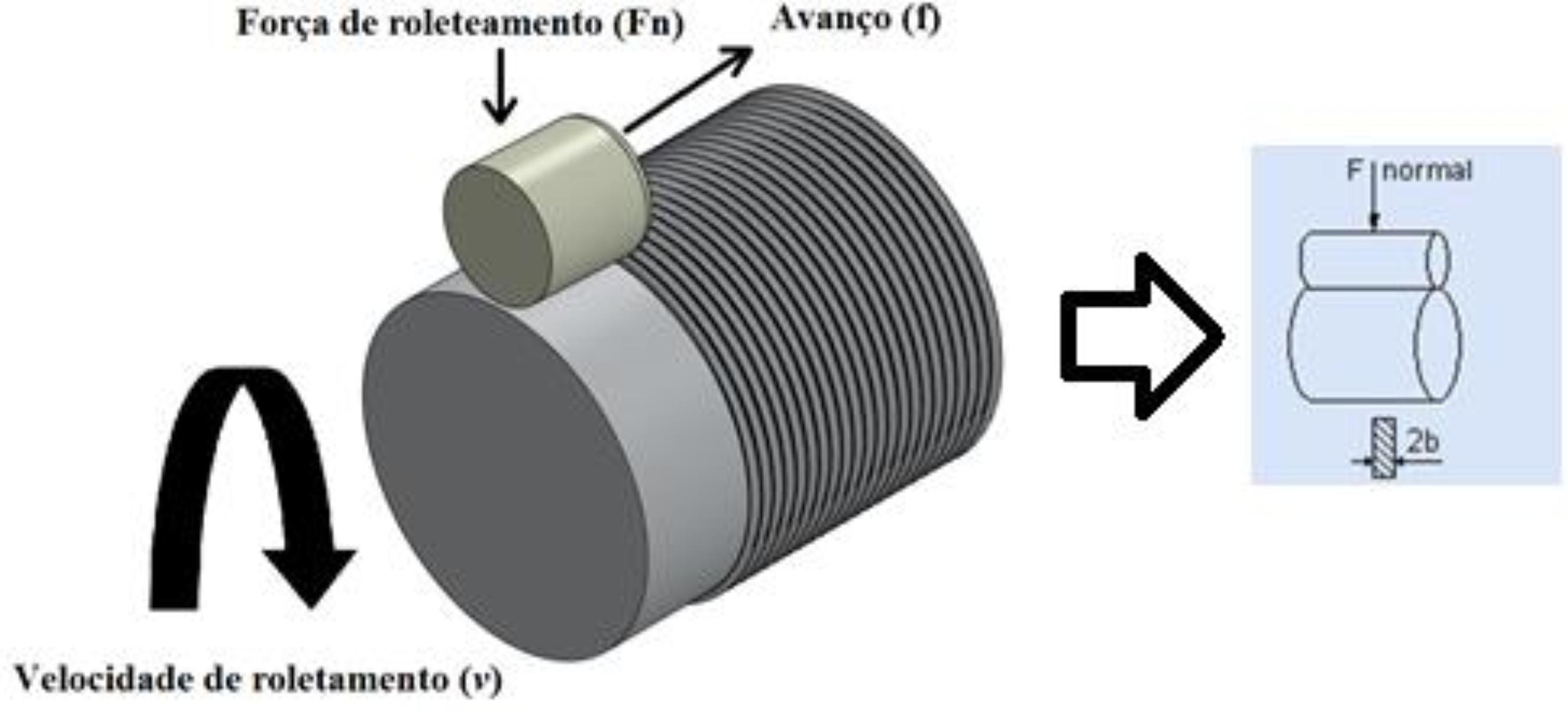

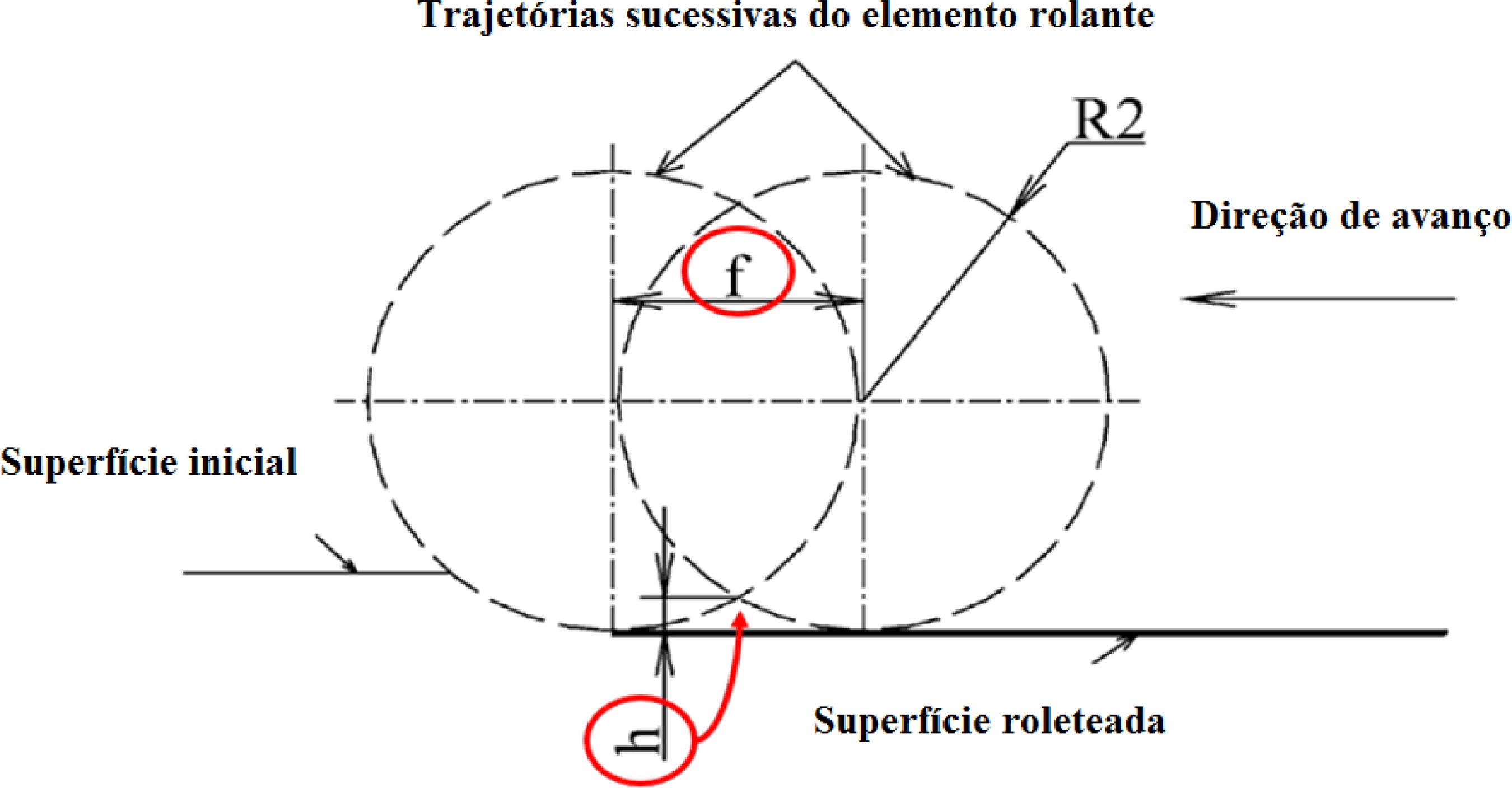

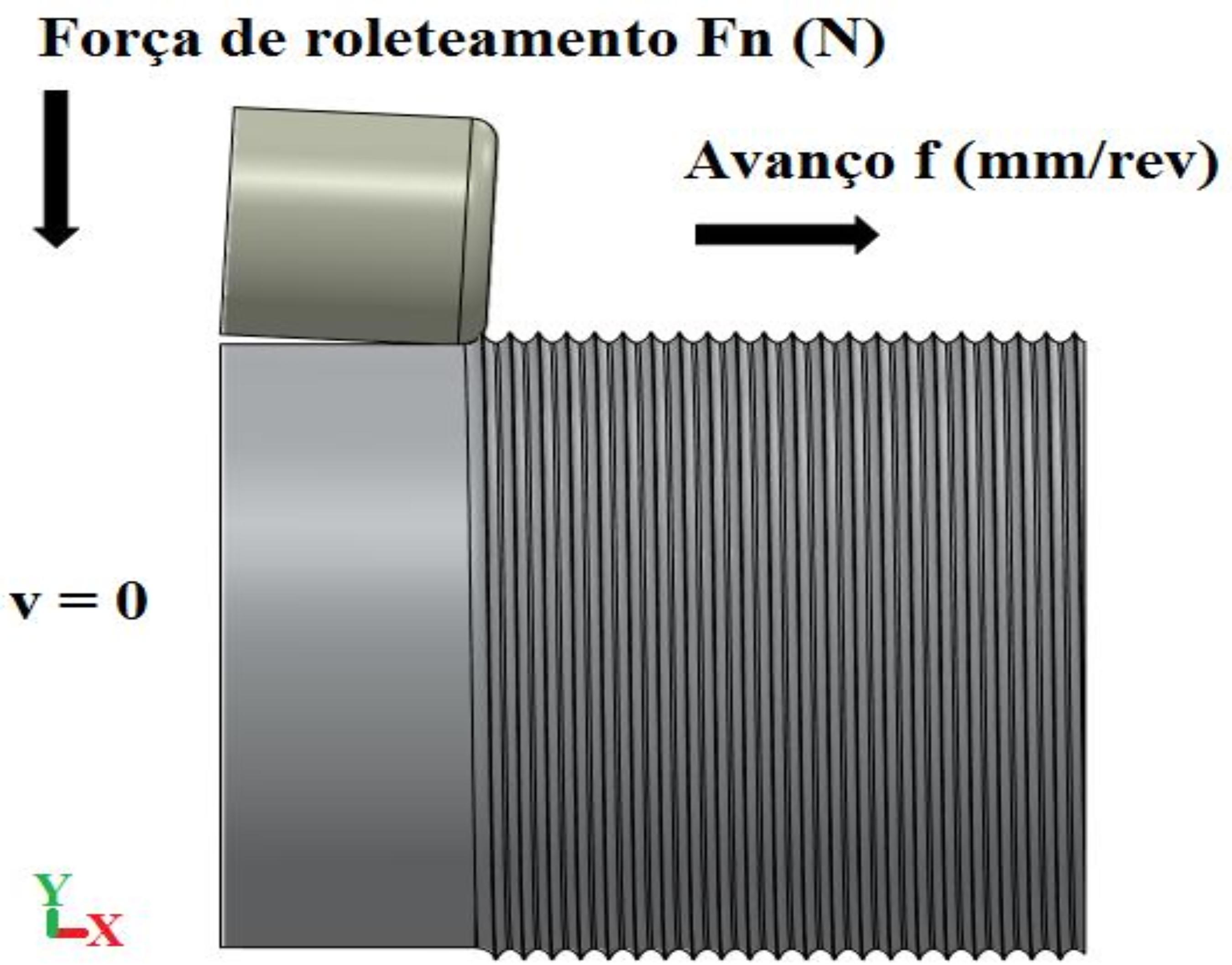

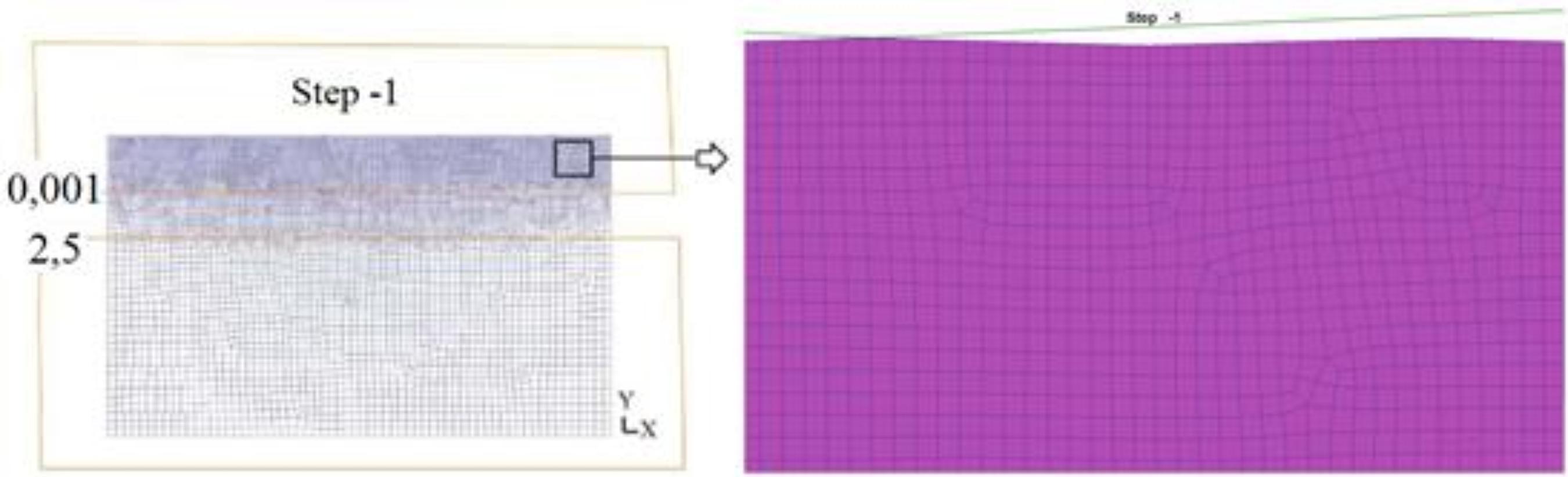

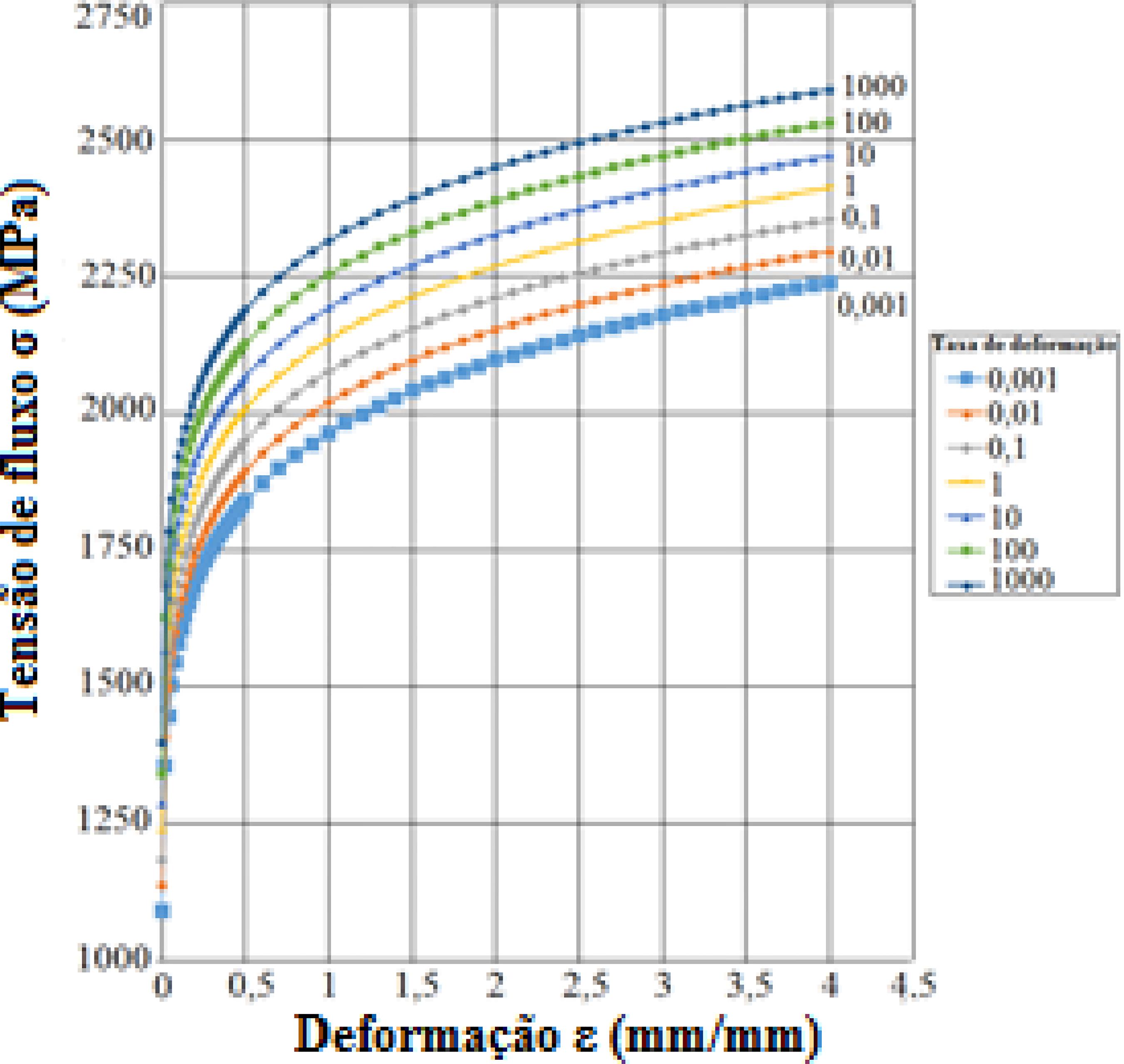

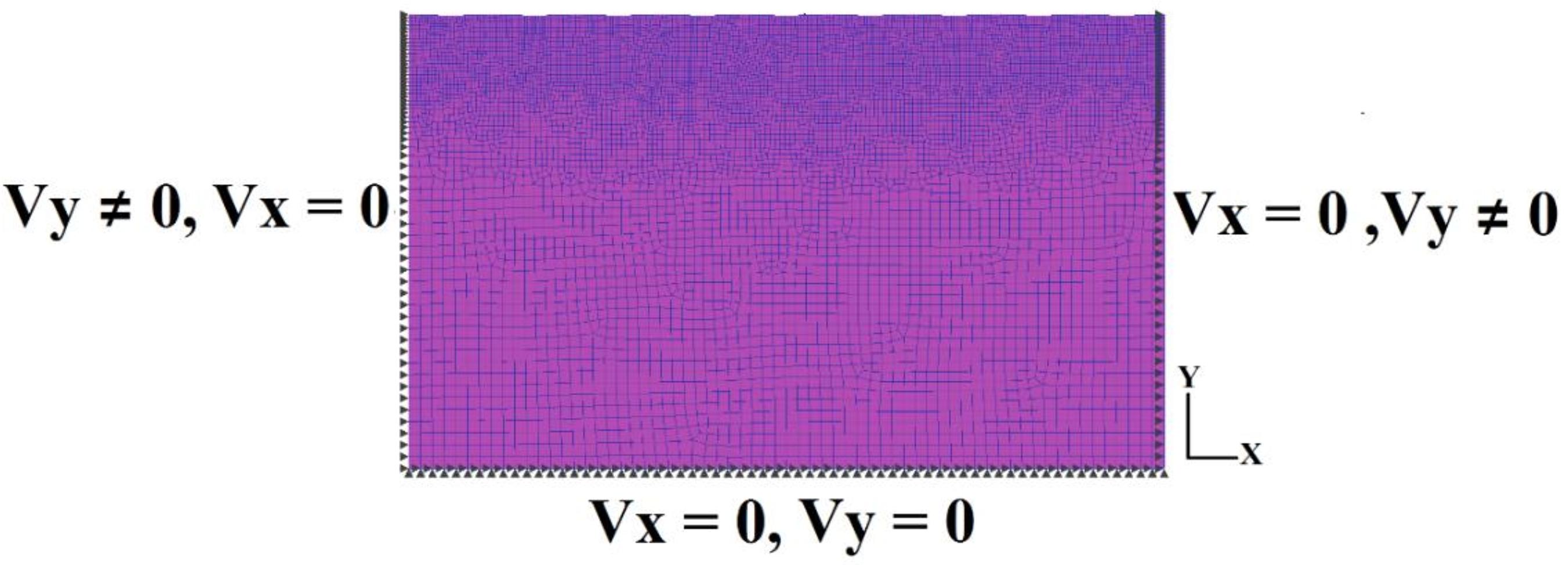

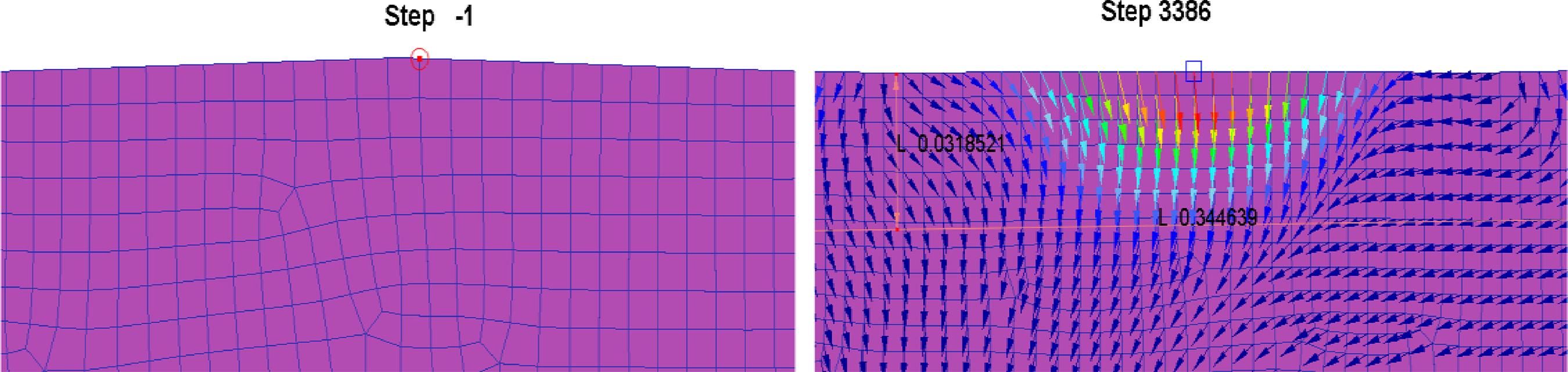

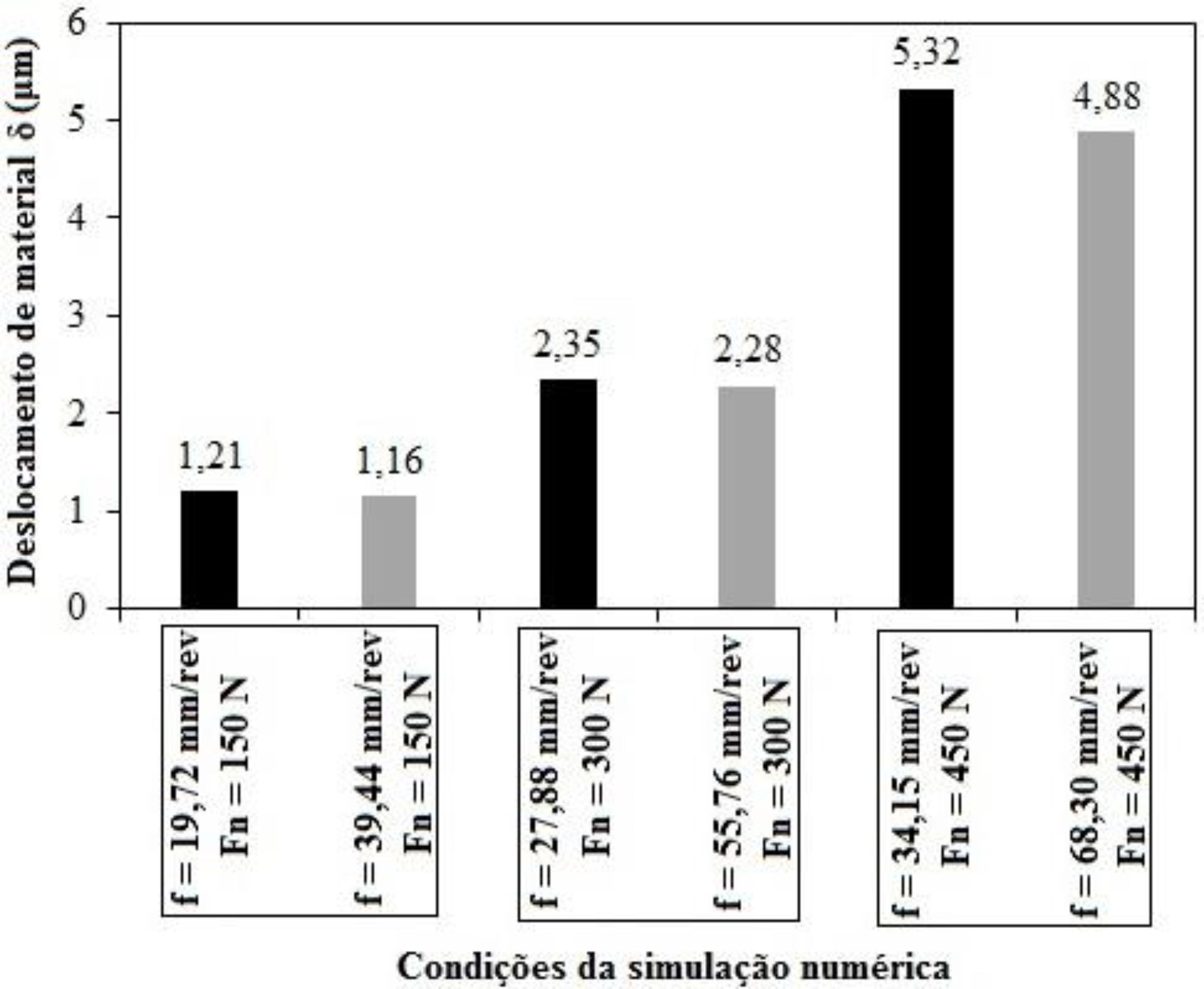

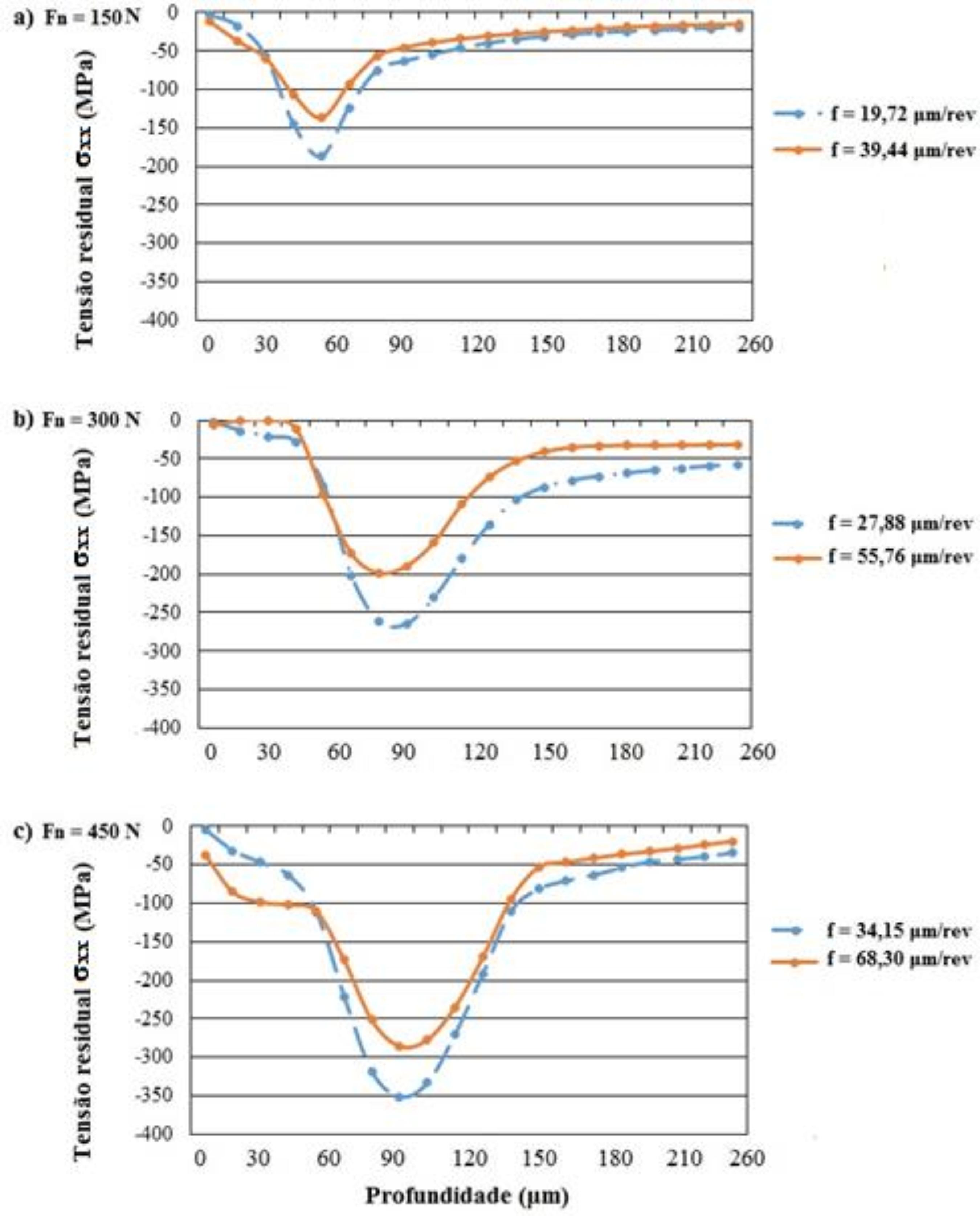

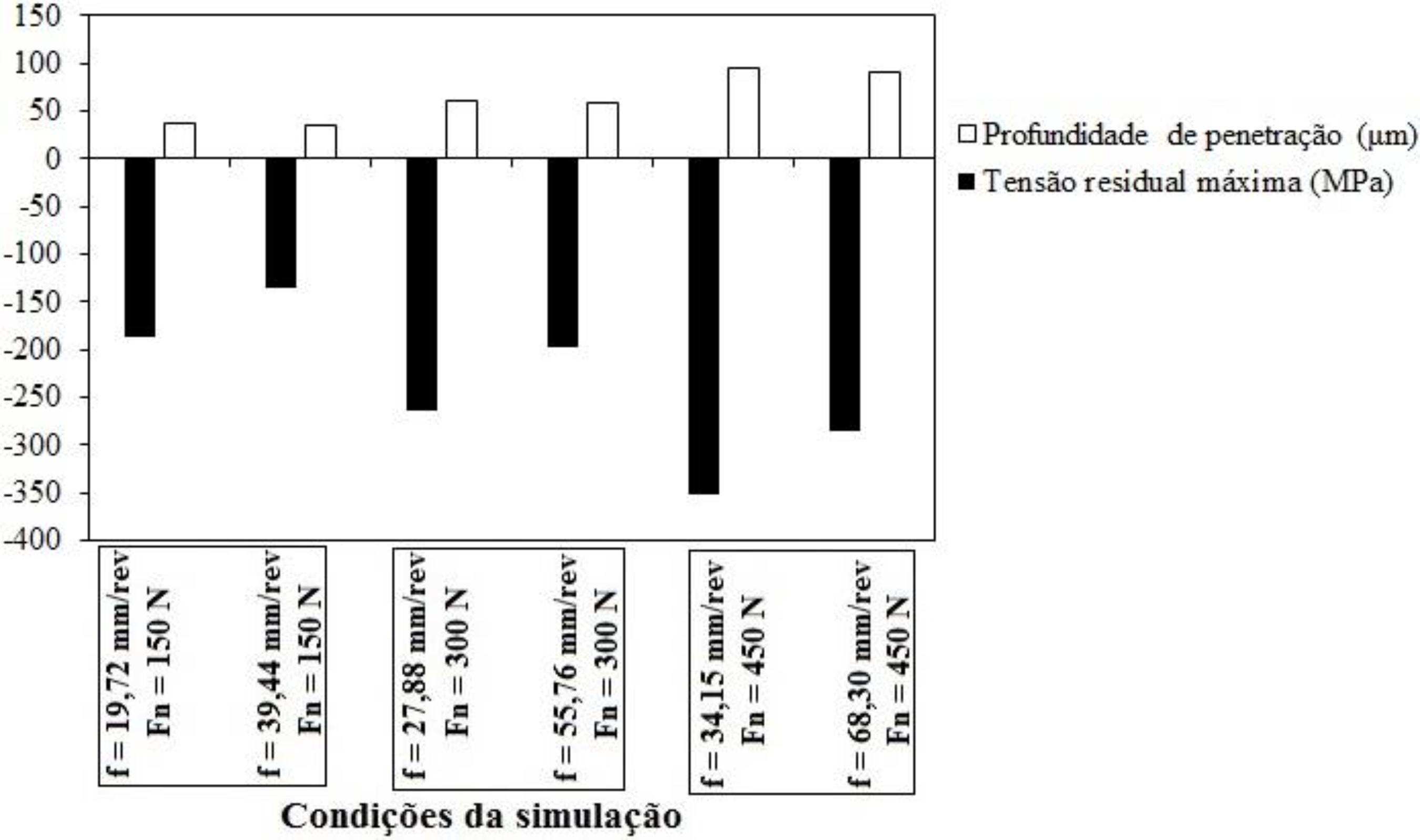

Metallic components for engineering applications are often employed under the action of thermal and mechanical loads, which tend to reduce their lifespan. Mechanical surface treatments appear as an alternative capable of extending the service life of these materials. These processes act by plastically deforming the surface, increasing its surface hardness and inducing compressive residual stresses. The combination of these factors leads to an increase of the part lifespan because it diminishes the nucleation and propagation of cracks, which are responsible for material failure by fracture. Although surface treatment processes such as shot peening and laser shock peening are widely used to induce compressive stresses, roller burnishing not only induces compressive stress and increases surface hardness, but also promotes the reduction of surface roughness. In this work, two-dimensional numerical simulation using the Finite Element Method (FEM) method for roller burnishing the hardened ABNT 4140 (40 HRC) steel was performed, considering the tool a rigid element, while the part was assumed as elasto-plastic. Burnishing force and feed rate were selected as input parameters which influence on roughness and residual stress induction was investigated. Moreover, unlike other two-dimensional numerical models, the initial roughness of the part was introduced in order to assess its influence on the process. In addition to that, the numerical simulation occurs in the interval from one peak to the other, defined by the feed mark of the previous turning operation (0.2 mm). The HertzWin software was used to define the feed rate for each condition, which was based on the half contact width (b) obtained for each force separately. The numerical results suggest the reduction of roughness and the increase of compressive residual when the rolling force is increased and the feed rate is reduced.

Keywords

Turning; surface quality; roughness; fatigue life; AISI 4140 steel