Abstract:

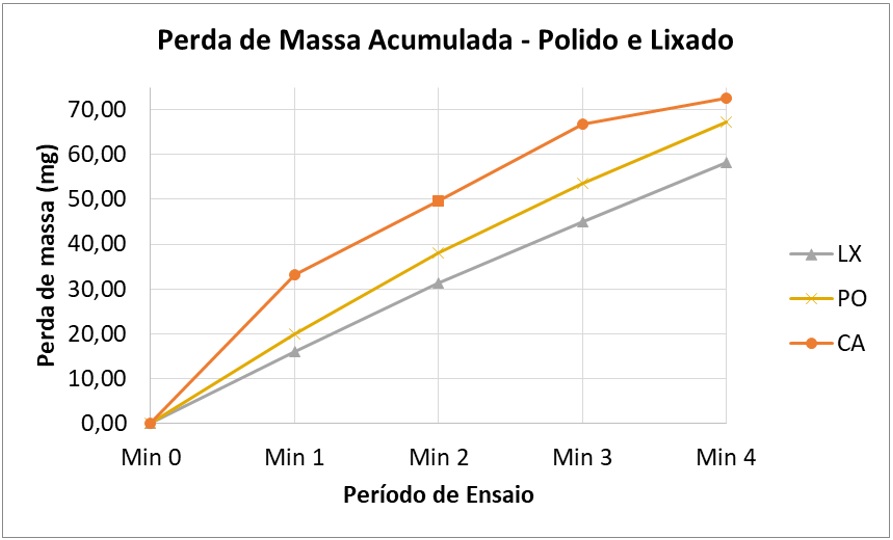

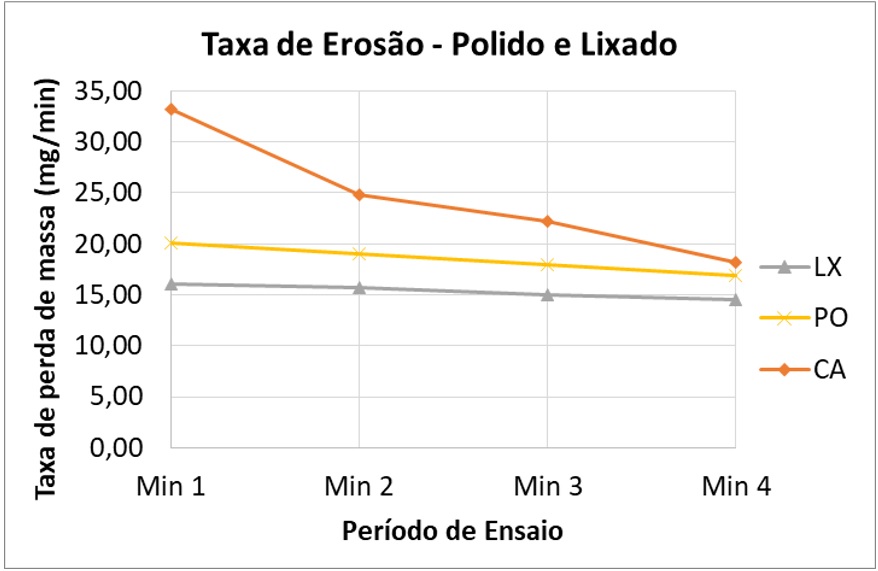

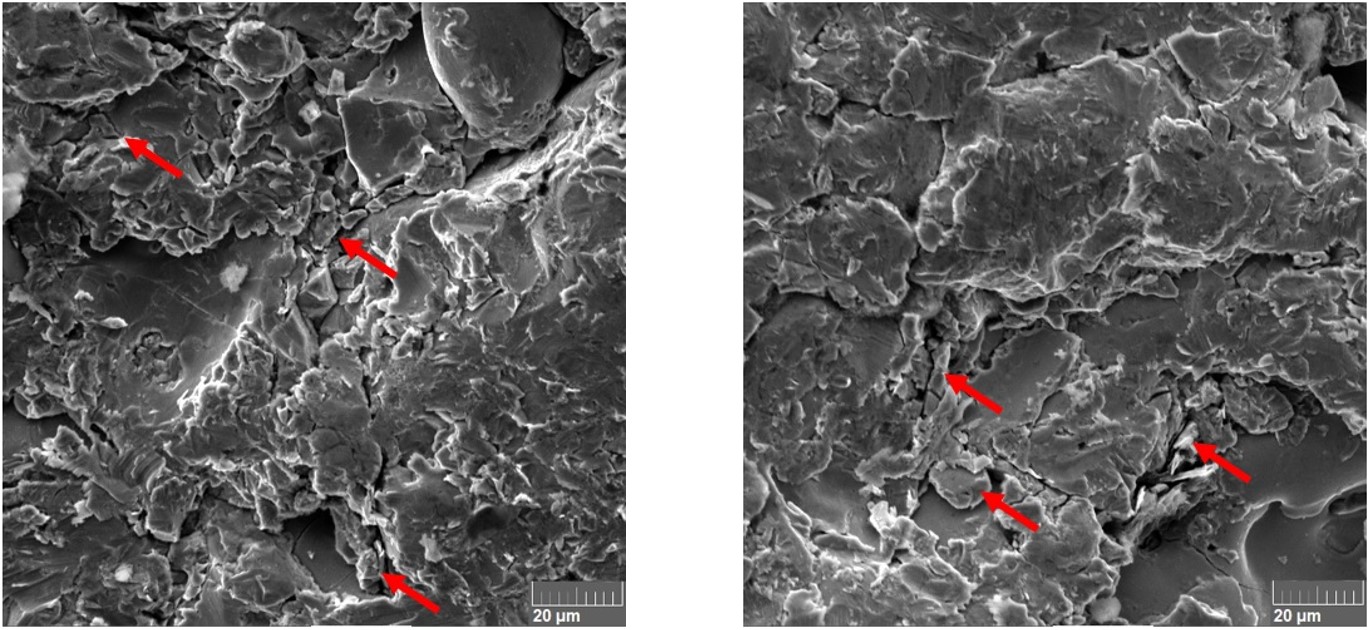

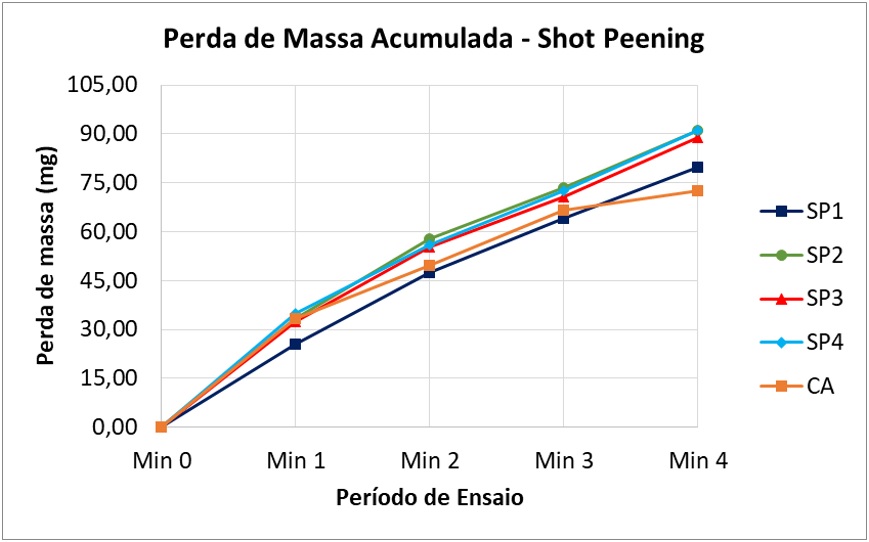

Currently in Brazil, more than 60% of electric energy comes from hydro generation. In hydroelectric generation, some mechanical components are often exposed to wear phenomena, and solid particle erosion is one of the most usual. The use of coatings is an interesting alternative to reduce the wear and thermal spray technology appears as a relevant solution with minimum impact to the component substrate. In this work, a commercial wear resistant alloy was applied on carbon steel substrate by Arc Spray Process (ASP) and subjected to surface finishing of single-step sanding, full polishing and shot peening. Coatings with and without surface treatments were evaluated for morphology and hardness and then subjected to slurry jet erosion tests. The results indicated that the coating tends to present the same erosion mechanisms expected for bulk materials. The surface sanding and polishing reduced the initial wear rates however, it did not compensate the mass loss caused by the finishing processes themselves. The shot peening reduced the erosion resistance of the coating.

Key-words:

Erosion; Thermal spray; Slurry-jet; Coating

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail